How COM4 processing creates smoother, more durable yarns

Few things are as frustrating as a brand-new sweater or a favorite t-shirt developing those tiny, unsightly balls of fiber known as pills. Pilling can make even high-quality textiles look worn and old before their time. But what if there was a way to create yarns that inherently resist this pesky problem? Enter COM4 yarn processing, a technology that's changing the game in textile manufacturing and helping to deliver significantly more pill-free fabrics.

What exactly are pills, and why do they form?

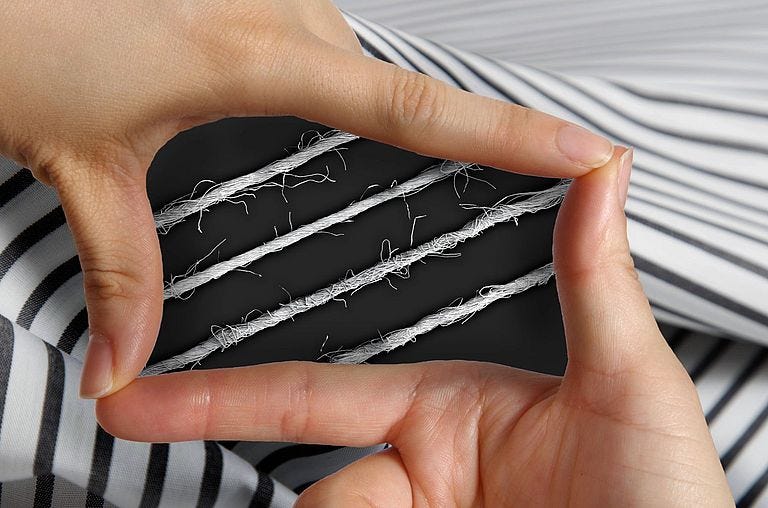

Before we dive into the solution, let's quickly understand the enemy. Pilling occurs when loose fibers on the surface of a fabric get tangled together through friction during wear and washing. These tangled fibers form small knots or balls that cling to the fabric's surface, making it look fuzzy and worn. Certain fibers and fabric constructions are more prone to pilling than others, but it's a common issue across many textile types.

COM4: A different approach to yarn spinning

COM4 isn't just one single spinning method; it's a brand name by Rieter that encompasses a range of advanced spinning technologies, including ring, compact, rotor, and air-jet spinning. While each of these systems has its own nuances, the underlying principle behind COM4 and its contribution to pill-free textiles lies in creating a more compact, well-bound yarn structure with significantly fewer protruding fibers.

In conventional spinning, there's often a "spinning triangle" where fibers are less controlled before being twisted into yarn. This can lead to more wild or loose fibers on the yarn surface. COM4 technologies, particularly compact spinning, utilize innovative methods like aerodynamic forces or mechanical compacting to ensure fibers are more parallel and tightly integrated into the yarn structure.

The "pill-free" secret: fewer loose fibers

The key to COM4 yarn's superior pilling resistance lies in this improved fiber integration. By minimizing the number of loose fiber ends on the yarn surface, there are simply fewer fibers available to tangle and form pills when subjected to friction. Imagine a rope made of tightly wound strands versus one with many loose ends; the one with loose ends is far more likely to fray and develop knots. COM4 yarns are like that tightly wound rope.

Beyond pill resistance: the added benefits of COM4 yarns

While the reduction in pilling is a major advantage, COM4 processing offers a range of other benefits that contribute to higher quality textiles:

Reduced hairiness: Less fiber protrusion means a smoother yarn surface, leading to fabrics with a cleaner, more defined appearance.

Increased strength: With fibers more effectively integrated and contributing to the yarn's core, COM4 yarns often exhibit higher tensile strength.

Improved downstream processing: The consistent quality and reduced hairiness of COM4 yarns can lead to fewer interruptions and higher efficiency in weaving, knitting, and finishing processes.

Enhanced fabric aesthetics and comfort: Fabrics made from COM4 yarns often have a clearer structure, better drape, and a softer feel due to the smoother yarn surface.

In Conclusion

COM4 yarn processing represents a significant advancement in spinning technology. By focusing on creating a more compact and uniform yarn structure with fewer loose fibers, it effectively tackles the common problem of pilling, leading to textiles that look better and last longer. So, the next time you enjoy a garment that maintains its smooth, fresh appearance wash after wash, there's a good chance COM4 technology played a role in its creation. It's a testament to how innovation in yarn production can make a real difference in the quality and durability of the fabrics we use every day.